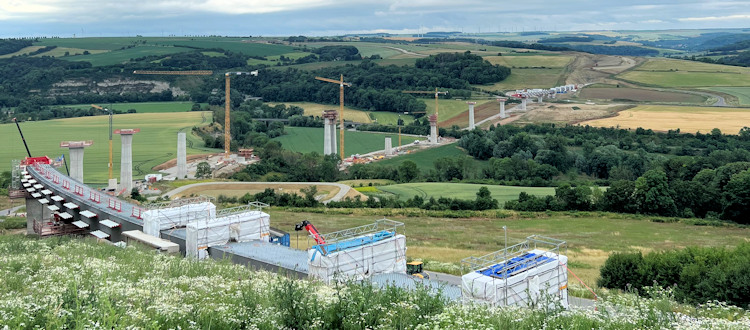

Saale Valley Crossing near Bad Koesen

Significant transport infrastructure project with a special focus on preserving flora and fauna

The Saale valley crossing is part of the new construction of the Bad Koesen bypass along the new federal highway 87, with the aim of relieving the town center of heavy through traffic and reducing pollution and dust formation. The project is being implemented by the consortium founded for the project, ARGE Saaletalquerung, consisting of the companies STRABAG, bridge construction branch South-East and Plauen Stahl Technologie, on behalf of the Saxony-Anhalt State Road Construction Authority, Regional Division South. The planning office IGS INGENIEURE was responsible for the construction management and the company SFF Ingenieure as well as the Engineering Office for Traffic Facilities (Ingenieurbüro für Verkehrsanlagen – IBV) were responsible for the construction supervision. The engineering office KREBS+KIEFER Ingenieure was appointed as inspection engineers. Construction began in March 2022 and is scheduled for completion in 2025.

The new bridge not only crosses the Saale, but also a nature conservation area, which is why particular attention was paid to the ecological impact on flora and fauna. It also crosses the Leipzig-Erfurt and Munich-Berlin ICE railway routes, road 203 and a farm track. It stretches over a total length of 1,226 meters and rises up to 65 meters above the Saale river. This makes it one of the largest viaducts in Eastern Germany. The special feature of this construction project is the hybrid construction method, which was chosen due to special topographical conditions. The central section, a 130 meter long main span over the Saale river, is being built as a haunched prestressed concrete box girder in cantilever construction. The northern and southern ramp areas, on the other hand, are being built as a steel composite structure using the incremental launching method. The challenges of this project lie in the curved course of the bridge and the gradient (varying 6% and 3%) of the route. To ensure a uniform load-bearing structure, the prestressed concrete superstructure and the steel structure are monolithically connected to form a jointless load-bearing structure.

A total volume of around 30,000 m³ of ready-mixed concrete is planned for the project – around 80% of which is F3 consistency, of which around 20,000 m³ has already been delivered from the Naumburg and Freyburg plants of Dyckerhoff Transportbeton Thüringen. In close cooperation with the Dyckerhoff test center in Muelsen (concrete technology branch of Dyckerhoff Beton) and the quality management of STRABAG, suitable recipes were developed for the respective requirements.

The massive components – the bored piles as well as the piers and abutments of the pile head slabs – were constructed using concrete according to additional technical contract conditions and guidelines for civil engineering structures (ZTV-Ing) with strength classes C30/37 and C35/45. The blast furnace cement HOZ Doppel LH (na) [CEM III/A 42.5 N-LH (na)] was predominantly used for this. In addition, various formulations based on a blended cement consisting of the aforementioned HOZ Doppel LH (na) and the Portland limestone cement PKZ Doppel [CEM II/A-LL 42.5 R] were developed in order to achieve optimum strength development, which were used in various concretes: for the piers and the steel composite superstructure with strength class C35/45 and for the pier heads and the prestressed concrete superstructure as C40/50 concrete. For the abutments/wings and the chamber walls, a concrete of strength class C30/37 is used, which is also produced with HOZ Doppel LH (na). The concrete with air-entraining agents of strength class C25/30 for the bridge caps and cornices also contains PKZ Doppel.

The concretes used in this project were largely produced using regional raw materials: All the cements used were produced at the Deuna cement plant in Thuringia, which is certified with the Gold label by the Concrete Sustainability Council (CSC). Most of the sand and gravel for the concrete came from the region.

In total, the construction project covers a distance of around 13.25 km, including seven bridge structures, seven drainage basins and a noise barrier. In the surrounding forest areas, an approx. 180 m long bat flyover on the bridge and a seven meter wide and three meter high bat tunnel near the Tultewitz location will ensure the protection of the nocturnal mammals living in this area. Other nature conservation measures include the dismantling and renaturation of road sections, reforestation and guide planting, extensification of farmland and the creation of field hedges, rows of trees and semi-arid grassland.

The Saale valley crossing plays a crucial role in the region's transport infrastructure. It not only connects Bad Koesen with neighboring towns and municipalities, but also acts as an important transit route for supra-regional traffic. The aim of the project is to create a smooth flow of traffic on this busy route, which will not only relieve congestion in the town center but also preserve Bad Koesen's spa status.

(Photos: 1+10 of the slideshow - © KREBS+KIEFER | Visualization)

Dyckerhoff GmbH, Product Marketing

For further information, please contact:

Iris Weise-Rosch, Tel.: +49 611 676-1187

marketing@dyckerhoff.com